Intelligent Drier Control

Intelligent grain drying to cut costs and increase productivity

Drying grain precisely is a complex process, but doing it correctly achieves the best possible grain quality for the best price. Relying on manual drying can risk either not attaining the desired moisture content, or over-drying the grain which is a costly exercise. Overstepping the mark by drying to 13% instead of 14% can typically add up to 20% to your energy bill, whilst simultaneously reducing your driers capacity by up to 16%. This is where the Tornum IDC software can help…

Let the Tornum Intelligent Drier Control (IDC) do all the hard work!

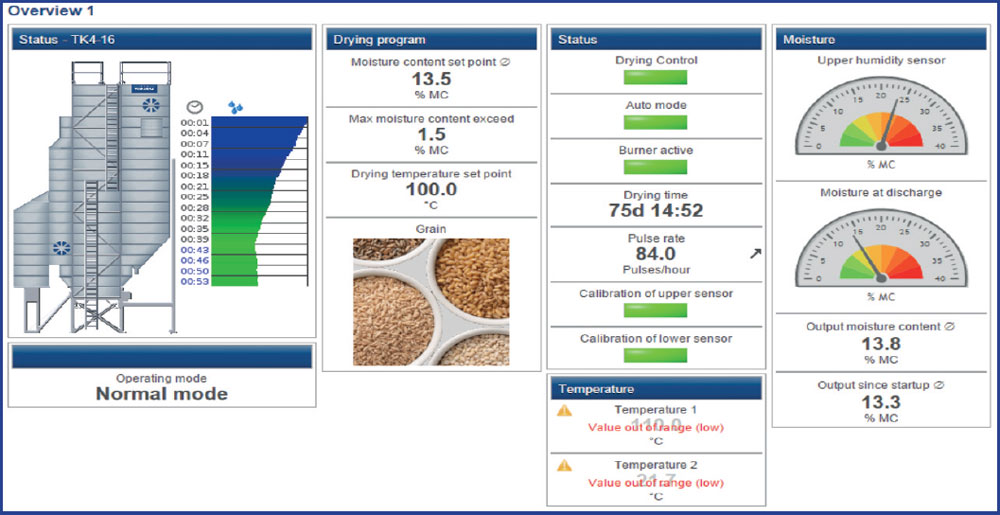

IDC is a software based control system which can be used in continuous flow grain dryers to monitor and control the out-going moisture content. One sensor is placed in the upper drying section of the drier and measures the incoming moisture content. The second sensor is placed in the cooling zone close to the drier outlet and measures the outgoing moisture levels. By using and monitoring this information, the control unit sets the speed of the drier discharge in order to obtain the required average moisture content of the grain, irrespective of outside weather conditions. By taking the guesswork out of the drying process the risk of over-drying is kept to a minimum and consistent moisture levels are more easily achieved.

As fewer man-hours are needed to monitor the drying process, labour costs are also reduced. The IDC kit is available in 4 different sizes with 2 or 4 moisture sensors depending on the drier size. Temperature sensors can also be provided if more detailed information is required about the drying process.

Advantages

- •Improved records and traceability of the drying process

- •Reduced dryer costs

- •Increased dryer capacity

- •Total control over the drying process

- •Change grain type and drying recipe at the touch of a button

- •Optimised drying process

- •Intelligent software adapts to conditions

- •Easy to install, easy to use

- •An instantly profitable investment

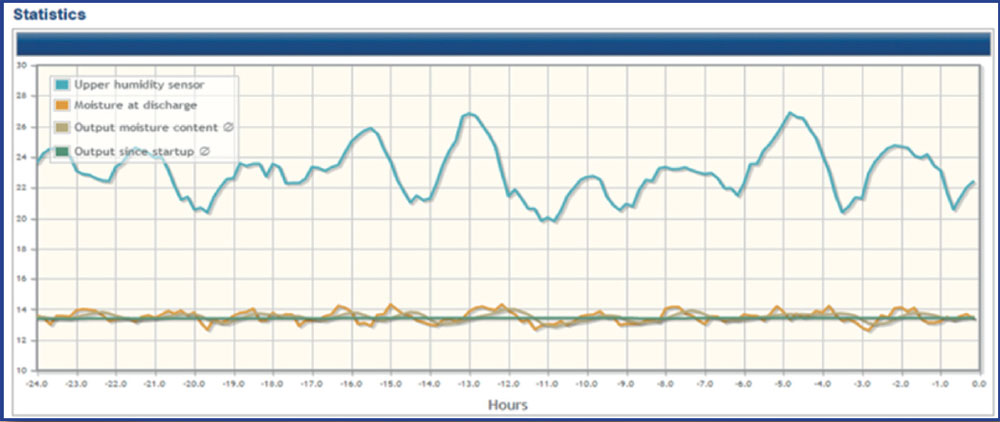

As demonstrated below the user-friendly IDC interface shows all the information needed.

This graph of incoming and out-going moisture content is just one of the ways the statistics collated by the IDC can be presented in an easy to read format.